Are you looking for a reliable book printing supplier?

The preparation of a book estimate usually requires 24 to 48 hours. For non-book items or combined orders, processing may take longer. Kindly reach out to your account manager and submit the following information.

Title

Print Quantity

Contents

Binding Format

Paper material & Printing Color

Finish Treatment

Shipping Requirements

Any special production/packaging requirements

General Timeline for Your Project

Prepress

The prepress process typically requires 2-3 days for an online PDF approval. Physical color proofs or ozalids typically take around 7 working days to arrive. Be sure to review your prepress workflow with your sales representative.

Below is some special things you should pay attention when you create the print artworks:

- Use CMYK color mode.

- Ensure image resolution is no less than 300dpi.

- Label and organize files by part numbers and names according to the spec sheet.

- Embed all texts and fonts.

- Use vector illustrations for die cuts and place them in different layers.

- Use pure black color settings: C: 0%, M: 0%, Y: 0%, K: 100% to avoid color inconsistencies.

- Keep a 3mm bleed on each side. All artwork and background colors should extend into the bleed area.

- Maintain a 3mm margin area from the artworks to the die-cut lines.

- For rigid box or hard covers: keep a 3mm bleed plus a 15mm wrap to ensure they can be wrapped around the edges.

Production

Standard hardcover or paperback books have a 4-week printing and binding timeline. Projects requiring specialty finishes or significant manual needs may necessitate additional production time. We will provide you with a detailed schedule upon request.

Shipping & Delivery

Door-to-door transit takes approximately 5–6 weeks to US and European hubs, and 3 weeks to Australia and New Zealand.

Express shipments (DHL/UPS/FedEx): 3-4 working days

Shipping Term Available:

We offer multiple shipping terms, including EXW (Ex Works), FOB (Free on Board), CIF (Cost, Insurance, and Freight), DAP (Delivered at Place), DDU (Delivered Duty Unpaid) and DDP (Delivered Duty Paid). Alternatively, you may arrange your own freight forwarder to collect the goods directly from our factory.

With our advanced machinery, skilled engineers, and experienced manual team, we are fully equipped to handle high-volume book production across various binding types. Our mature production process ensures consistent, reliable quality, making us a trusted partner for publishers with diverse and demanding printing needs.

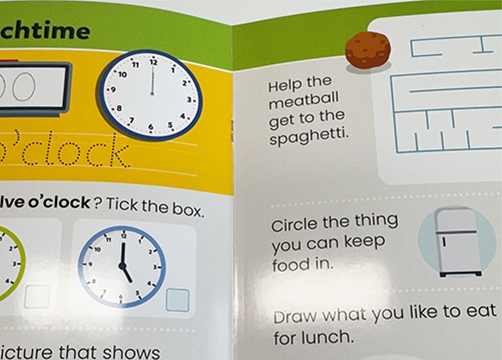

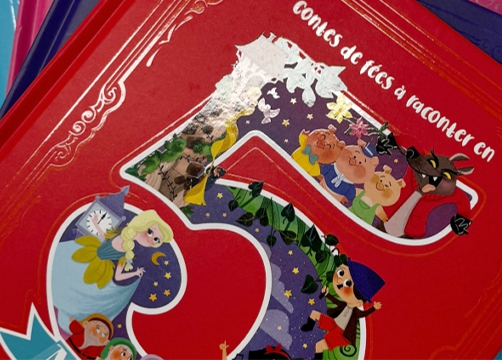

Printed Books

Hard cover with square spine

Hard cover with rounded spine

Hard cover book with edge printing

Hard cover book with jacket

Flexi-bound

Perfect bound

Perfect bound with section sewn

Perfect bound with edge printing

Perfect bound with gatefold

Board book – paper back

Board book – Hard cover with rounded corners

Board book with touch and feel

Board book with pop-up

Board book with slide and pull

Board book with sound module

Exposed Wire-O bound – paper back

Exposed Wire-O bound – Hard cover

Concealed wire-O with rounded spine

Semi-concealed Wire-O

Spiral bound

Book block binding

Saddle Stitch

None-book products

Card’s Box Set

Puzzle

Rigid lid and base box

Magnetic box

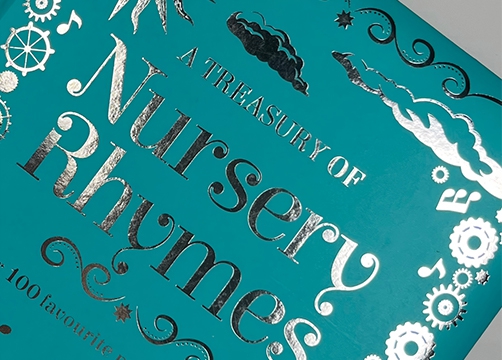

Beyond standard finishes like varnish, UV coating, and lamination, there are a variety of special treatments available to elevate your book’s design. These unique techniques enhance texture, visual appeal, and overall sophistication, ensuring your publication stands out. We offer an array of specialty finishes to help you create a truly distinctive and memorable product.

Beyond printing and producing paper-based items, our factory can also assist in sourcing a wide range of project components from China’s competitive supply market. From animal fur, plastic parts, stationery items, sound modules and other custom materials, we work with trusted suppliers to ensure quality, cost efficiency, and smooth integration with your production needs.

Blister

EVA Padding

Fabric puppet

Film

Fur material

Game components

handle

Jelly Sticker

Mirror

sound module

Wipe clean pen

Wooden parts

Ready to bring your book to life?

From idea to finished copy, we're here to support you every step of the book printing journey. Request a free quote today!

Copyright© ZHONGTIAN'S MANFA-CTURING CENTRE 2025 all rights reserved